I’ve been going to the Atlanta Film Festival since the early 90’s, and for the last 5 years or so I’ve been taking that whole week off work and going to every screening that appeals to me. This year was no different … well, no, it was different this year, because I wasn’t able to take the week off from work — too much going on. I still got to see about the same number of screenings though.

So, since I’ll forget if I don’t externalize, here’s the results, in order from best to worst:

Best of the festival

Rize ( AFF desc / website ) — absolutely incredible; saw it twice

Unknown White Male ( AFF desc / website ) — awesome; if you forgot your identity, after you’d restarted your life with a new identity would you still care about getting your old memories back?

Seoul Train ( AFF desc / website ) — documentary about the underground railroad (think human smuggling) trying to get people out of North Korea; bracing, searing, fantastic insight into the horrors of those trying to escape and those who try to help them do it

La Sierra ( AFF desc / website ) — about the teenagers and young men from the slums who make up part of the Colombian conflict; I have to say it was pretty great, because 3 months later it still sticks with me. I saw City of God on DVD recently (including the 1 hour documentary News From A Personal War)and it recalls the same sort of lawless chaos — actually, not lawlessness, really, more like brutal ghetto law.

Interesting

Fall of Fujimori ( AFF desc / IMDB ) — a very strange documentary, smacked of pro-Fujimori propaganda; I’d love to hear the back story.

Boys of Baraka ( AFF desc / website ) — threatened to be feel good crap (hey, it won the audience award, whaddya expect) but was actually alllllright

Twist Of Faith ( AFF desc / website ) — sexual abuse at the hands of pedophile priest; full grown men grapple with confronting the events of their youth; insightful view into how people try to stand up for what’s right, and fail

Take it or leave it

Documentary shorts ( AFF desc ) — not horrible

Education of Shelby Lynn (documentary) ( AFF desc / website )– standard POV fare

Kill Your Idols ( AFF desc / IMDB ) — yet another fawning treatment of the New York nowave/underground scene; surprisingly dull

Liberace of Baghdad ( AFF desc / website ) — vaguely interesting insights into the life of average folks in post Freedom-On-The-March Baghdad; wanted to like it but it was weak and went nowhere; maybe that’s the point.

Please kill me

Hooligans ( AFF desc / IMDB ) — why? why do I keep going to these crappy narrative pics? They are always complete shit, especially the ones with some B-list actor in it (Paul Reiser, Elijah Wood, whatever). And of course it was preceded by some local huckster on stage hyping the shit out of it. So bad I left early. No wait, I actually forced myself to sit through the whole thing, waiting for it to redeem itself, and bolted as soon as the credits started. Elijah Wood fans will love it, I’m sure. Well, at last it wasn’t as bad as the 2004 festival’s The Last Goodbye, which taught me to never EVER attend screenings of locally produced films, and be gunshy about narratives in general. See, the problem is that occasionally there is a good narrative — I loved 2004’s Primer. You gotta play to win …

“weird” narrative shorts collection ( AFF desc ) — crap crap CRAP

Emmanuel’s Gift ( AFF desc / website ) — you know, I can’t believe they actually let this drivel into the festival; I mean, I know that they tend to save the schmaltziest, most geriatric fundraising fluff for the Wednesday Carter Center screening, but this is ridiculous. I guess word got out though, because there were fewer people there than I’ve ever seen at an AFVF/AFF Carter Center screening. Alas, I went and suffered through the whooooole thing (“it’s just a little saccharine, it’s still good, it’s still good!”)

Honorable mention for movies I planned to see but couldn’t; thanks IMAGE!

William Eggleston in the Real World ( AFF desc ) — even if IMAGE could have projected it properly, I still suspect it would have been mindnumbingly dull; not all subjects work on the big screen, folks.

MANA: Beyond Belief ( AFF desc / website ) — Damn it I wanted to see this, and damn it if IMAGE seems to have entirely forgotten how to run their own film festival!

The Beat That My Heart Skipped ( AFF desc / website ) — ditto; sign on the door when I arrived to see it. At previous festivals, IMAGE knew how to get the word out about schedule changes; that’s a skill that they no longer have.

In total, a noticeable step back from recent years. Hopefully IMAGE can recover.

So very very tired. I guess we’ve been walking 8-10 miles a day and we’re hurting! Everywhere you go is by subway or train and all the stations are well below the city so you have to walk up and down stairs all day to get in/out of the stations. Our legs hurt in all kinds of ways. Seeing an escalator is a blessing. The stations are incredibly busy, the busiest in the world, and it’s fascinating to watch the people come and go (and learn not to get flattened). You figure out which line, which station, how much, buy a ticket, put the ticket in the machine, keep the ticket handy because you need it when you get out, and go go go.

So very very tired. I guess we’ve been walking 8-10 miles a day and we’re hurting! Everywhere you go is by subway or train and all the stations are well below the city so you have to walk up and down stairs all day to get in/out of the stations. Our legs hurt in all kinds of ways. Seeing an escalator is a blessing. The stations are incredibly busy, the busiest in the world, and it’s fascinating to watch the people come and go (and learn not to get flattened). You figure out which line, which station, how much, buy a ticket, put the ticket in the machine, keep the ticket handy because you need it when you get out, and go go go. We also went to Ueno, via a marketplace where they sell lots of American goods. (The Japanese are crazy about Mickey Mouse, Sesame Street, Levis and Winnie the Pooh.) In Ueno we went to a park where there were different artists set up along a long promenade. Some were singers, one was a comedian, others were musicians. We turned a corner and a young man was set up playing a theremin! That was a weird thing to come across. We also saw people feeding tofu to a feral cat colony.

We also went to Ueno, via a marketplace where they sell lots of American goods. (The Japanese are crazy about Mickey Mouse, Sesame Street, Levis and Winnie the Pooh.) In Ueno we went to a park where there were different artists set up along a long promenade. Some were singers, one was a comedian, others were musicians. We turned a corner and a young man was set up playing a theremin! That was a weird thing to come across. We also saw people feeding tofu to a feral cat colony.

I have no idea….

I have no idea….

ER.

ER.

We walked from there over to the river boat to take a boat ride down to Odaiba. We rode on this bizarre river boat which looks like the boat from 20,000 Leagues (that’s the “Rainbow Bridge” in the background). The boat went down the Sumida River, which is the most central of several rivers that course lazily through Tokyo. We got to see the back of the Tsukiji fish market, where the boats pull up and unload their catch, I guess. Another cruise available was the “Happy Dog Cruise”, where once again unsuspecting dogs are sequestered to be petted and admired by the pet-starved Japanese. The boat’s destination was Odaiba, which is a manmade island in Tokyo bay built up with underattended entertainment destinations and corporate high rises. Think city planners run amok.

We walked from there over to the river boat to take a boat ride down to Odaiba. We rode on this bizarre river boat which looks like the boat from 20,000 Leagues (that’s the “Rainbow Bridge” in the background). The boat went down the Sumida River, which is the most central of several rivers that course lazily through Tokyo. We got to see the back of the Tsukiji fish market, where the boats pull up and unload their catch, I guess. Another cruise available was the “Happy Dog Cruise”, where once again unsuspecting dogs are sequestered to be petted and admired by the pet-starved Japanese. The boat’s destination was Odaiba, which is a manmade island in Tokyo bay built up with underattended entertainment destinations and corporate high rises. Think city planners run amok. I have to say, I’m pretty obsessed with the concept of people craving the interaction with animals. It’s so charming and sad all at once. Thankfully, Chris allowed himself to be dragged to yet another cat demo store there [Chris adds: when I can’t stand it anymore, I just go sit outside and continue reading my book about Buddhism; a great contrast, methinks]. It’s called Cats Livin’ and it’s like a little house with rooms, like the living room, the bathroom and the kitchen that the cats wander around in, trying to avoid the people who have paid to come pet and play with them.

I have to say, I’m pretty obsessed with the concept of people craving the interaction with animals. It’s so charming and sad all at once. Thankfully, Chris allowed himself to be dragged to yet another cat demo store there [Chris adds: when I can’t stand it anymore, I just go sit outside and continue reading my book about Buddhism; a great contrast, methinks]. It’s called Cats Livin’ and it’s like a little house with rooms, like the living room, the bathroom and the kitchen that the cats wander around in, trying to avoid the people who have paid to come pet and play with them.

We started with a breakfast of eggs, salad, big toast and coffee/tea. We headed to the Tama Region which is about 40 miles to the West of Tokyo. It took about 40 minutes by subway/trains. Purloand is a big park in Tama City Center — all the signs there say it’s “Hello Kitty’s Town!”. Purloand is all inside a huge building with 4 stories.

We started with a breakfast of eggs, salad, big toast and coffee/tea. We headed to the Tama Region which is about 40 miles to the West of Tokyo. It took about 40 minutes by subway/trains. Purloand is a big park in Tama City Center — all the signs there say it’s “Hello Kitty’s Town!”. Purloand is all inside a huge building with 4 stories.  It’s much like Disney World: anamatronics, dancing characters accosting children, attendants with smile holders, and LOTS of gift shops all through it.

It’s much like Disney World: anamatronics, dancing characters accosting children, attendants with smile holders, and LOTS of gift shops all through it. and children. The show involved some plot about HK being sad and going off to a magical land with fairies. The sets were ornate and the stage revolved. The costumes were either people in fluffy HK gear or people in fairy suits. It was the best singing, dancing, people in costumes show I ever saw. [Chris adds: it was deafening — children were crying; I think they had it so loud both to stun the kids into silence and to drown out the ones who’d snapped].

and children. The show involved some plot about HK being sad and going off to a magical land with fairies. The sets were ornate and the stage revolved. The costumes were either people in fluffy HK gear or people in fairy suits. It was the best singing, dancing, people in costumes show I ever saw. [Chris adds: it was deafening — children were crying; I think they had it so loud both to stun the kids into silence and to drown out the ones who’d snapped].

When we got home (after multiple trains) we stopped at an Italian restaurant in Shinjuku — some franchise chain not unlike a Denny’s, except for the weird remote control button at your table that you pushed to hail the waitress (in about 2.5 seconds, not kidding). It was packed with kids doing their homework together and had feel like a maltshop; very sweet.

When we got home (after multiple trains) we stopped at an Italian restaurant in Shinjuku — some franchise chain not unlike a Denny’s, except for the weird remote control button at your table that you pushed to hail the waitress (in about 2.5 seconds, not kidding). It was packed with kids doing their homework together and had feel like a maltshop; very sweet.

THEN. We went to the Dog/Cat/Ferret park, but the ferrets weren’t there or at least no one could tell us where they were. The deal with the Dog/Cat park is that people in Tokyo don’t have enough room/money to keep pets. Most live in rented apartments and the landlord won’t let them keep them. So there are “stores” and parks where people go to pet and hang out with cats and dogs.

THEN. We went to the Dog/Cat/Ferret park, but the ferrets weren’t there or at least no one could tell us where they were. The deal with the Dog/Cat park is that people in Tokyo don’t have enough room/money to keep pets. Most live in rented apartments and the landlord won’t let them keep them. So there are “stores” and parks where people go to pet and hang out with cats and dogs. The cats are in little individual rooms and rotated among a bigger room where people can go and pet them and play with them.

The cats are in little individual rooms and rotated among a bigger room where people can go and pet them and play with them. next door and you can “check out” a dog and take it for a walk. You can also go in a big pen where they run around and just pet a bunch of them. It was charming and bizarre. You should have seen the gift shop! Chris wishes he hadn’t.

next door and you can “check out” a dog and take it for a walk. You can also go in a big pen where they run around and just pet a bunch of them. It was charming and bizarre. You should have seen the gift shop! Chris wishes he hadn’t.

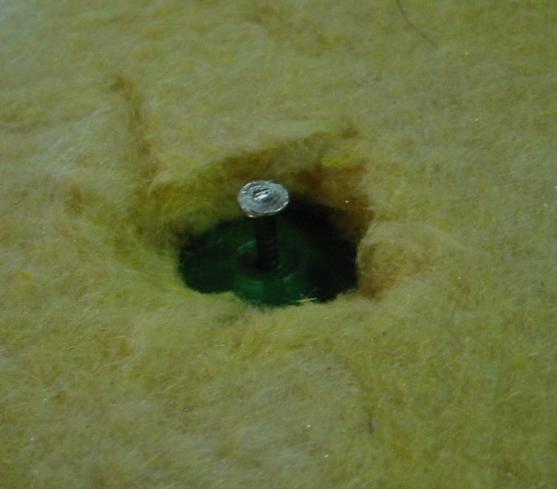

Update 20-Mar-2006: A couple weeks ago I finally got the front edging done — it’s called “nosing” and it’s this heavy vinyl stuff that is used on stair tread edges. Worked great on the curve as long as I used A) wallboard epoxy and B) lots of little finish nails.

Update 20-Mar-2006: A couple weeks ago I finally got the front edging done — it’s called “nosing” and it’s this heavy vinyl stuff that is used on stair tread edges. Worked great on the curve as long as I used A) wallboard epoxy and B) lots of little finish nails.

At the rear of the corporate campus where I work, we have a 250-foot-tall radio tower located among a field of large satellite antennas. About halfway up the tower is a platform that has for years been home to a nest for a couple of

At the rear of the corporate campus where I work, we have a 250-foot-tall radio tower located among a field of large satellite antennas. About halfway up the tower is a platform that has for years been home to a nest for a couple of  We have a campus-wide cable television system that feeds our own TV networks (plus a few not ours like Comedy Central and the Weather Channel) to all offices so they can see anything that’s airing at any time for whatever reason. I know the engineer who runs that system, and we managed to get my telescope fed into the cable system. I have a small video camera that hooks up to the telescope focuser (where the eyepiece normally goes) — it was a gift from my Dad about a year ago.

We have a campus-wide cable television system that feeds our own TV networks (plus a few not ours like Comedy Central and the Weather Channel) to all offices so they can see anything that’s airing at any time for whatever reason. I know the engineer who runs that system, and we managed to get my telescope fed into the cable system. I have a small video camera that hooks up to the telescope focuser (where the eyepiece normally goes) — it was a gift from my Dad about a year ago. We watched the hatchling grow from barely peeking over the edge of the [big, deep] nest, to being just as big as the adults, albeit with adolescent plumage. The mother hawk brought it kills (rats, pigeons, mmmm!) and the baby devoured them. It’s quite the gruesome sight, although I don’t think I ever laughed as hard as I did watching that baby gulp down the last big serving of rat.

We watched the hatchling grow from barely peeking over the edge of the [big, deep] nest, to being just as big as the adults, albeit with adolescent plumage. The mother hawk brought it kills (rats, pigeons, mmmm!) and the baby devoured them. It’s quite the gruesome sight, although I don’t think I ever laughed as hard as I did watching that baby gulp down the last big serving of rat.